Devices

At SPLinx we understand that investing in technology and modern solutions are a guarantee to working out and developing our own know-how, an investment in our future, as well as more effective and better quality work. For this reason we constantly expand our laboratory and machinery park and introduce modern IT work tools

We have several modern mixing devices for manufacturing oil-based and water-based inks as well as an especially high-performance gyro mixer at our disposal.

We can produce inks and varnishes from very small batches to huge (up to hundreds of kilograms) disposable production batches.

For the production of our inks we also use modern roller mills including a three-roll mill by Buehler, one of the major manufacturers of this type of machinery in the world.

The latest Ink Formulation 6 software in Manufacturer’s edition, which allows us to create our own colorimetric bases, helps us formulate the colours of spot inks as well as select new ink formulations.

The most extensive feature of Ink Formulation in Manufacturer’s edition allows us to freely choose suppliers of components and basic raw materials.

This solution allows us to keep our independence since we do not need to get associated with any corporation – we create our own, unique product series and colour mixes.

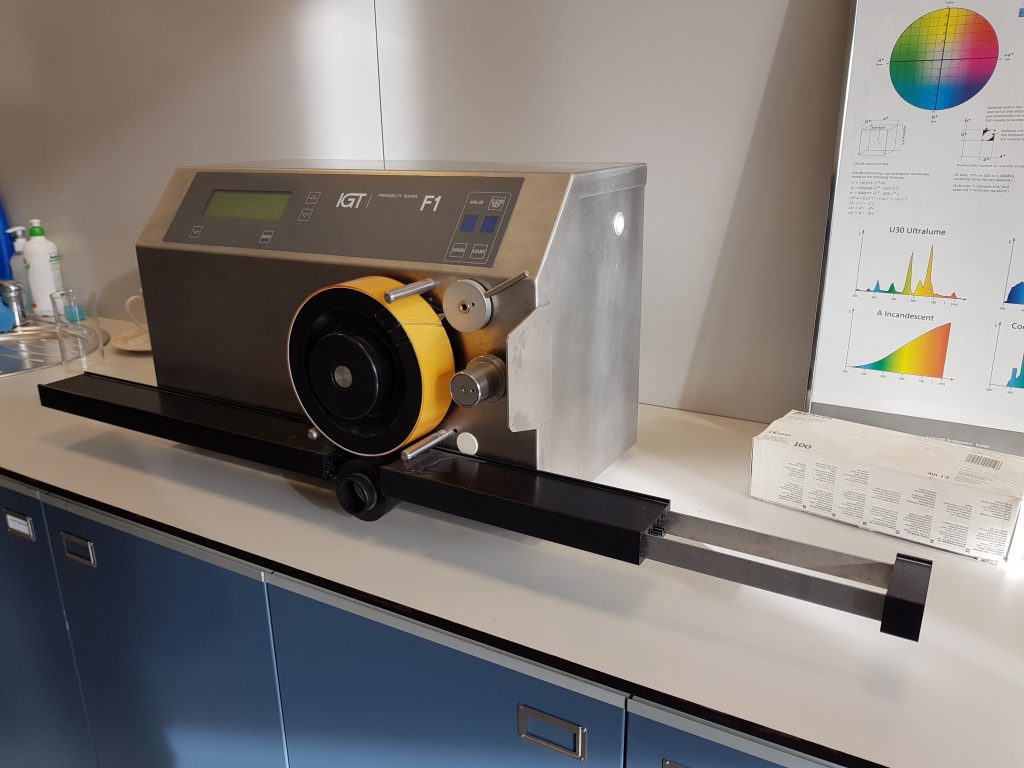

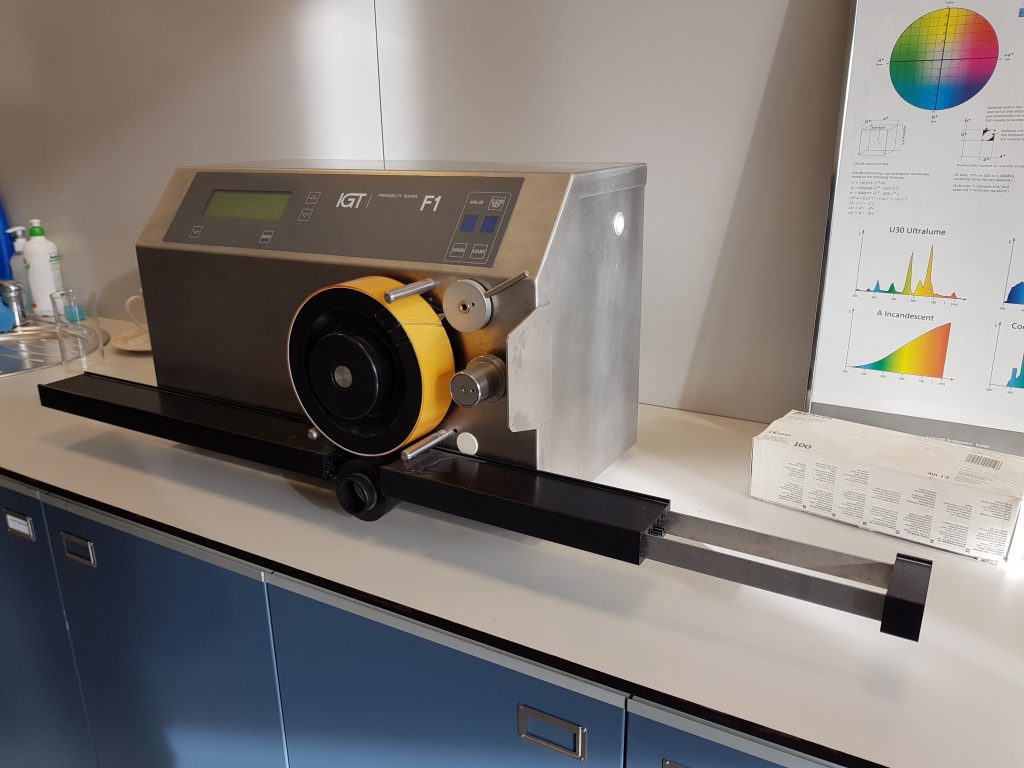

For comprehensive analysis and tests of the colours and rheology of our inks we use modern printing proofers:

Offset proofers: IGT Orange Proofer, two MiX-Test Proofers

flexo proofers: IGT Printability Tester F1 and K-Lox RK Print-Coat Instruments

spectrophotometers: X-Rite eXact Standard and X-Rite Ci6x

and many more devices and machines, big and small.