Securing labels and packaging against counterfeit and forgery. Part 3

Protection of products and their labels and packaging against counterfeit, copying, forgery is always a big challenge to a manufacturer. They engage in a kind of an „arms race” with forgers stealing their intellectual property. The forgers also learn how to replicate security features, trying to authenticate their copied or counterfeited product on the market. A simple security of a product against forgery may also result in copying the protection itself. A forger may try to obtain a special ink identified on the packaging or label of the original product (trade in special inks and varnishes is not regulated by law, neither at the national nor international level) and print the protection feature copied from the original on their imitation.

Therefore, the sophisticated approach to securing the packaging of original products against counterfeit, copying, and forgery becomes more and more important. In the range of special inks and varnishes can be found numerous products which are either very rarely or even never used in security purposes but have a huge potential to be used in such application. Potential forgers do not even know about most of them. In fact, they are actually known to a very small group of few professionals who work at the market of securities’ protection and to manufacturers of special inks and varnishes.

Photochromic inks

One quite sophisticated method to secure the label or packaging against counterfeit is the use of photochromic inks. These ink gain colour under the influence of ultraviolet irradiation. The source of such radiation can be either user-safe UV-A light emitter, commonly called the „blacklight” lamp, or sunlight (the colour disappears due to the part of UV light spectrum within the sunlight that reaches the Earth).

The area printed with photochromic ink is completely transparent; it becomes colourful as soon as it gest exposed to sunlight or light of a „blacklight” lamp. The protection can be placed at any part of a label or packaging because the print is invisible.

Attention should be paid not to make it too large and not to place is at exposed area because there is always risk that the average spectator would notice the light reflection where the print is placed (the ink in its transparent state looks like a varnish so the light reflection from its surface can be observed).

This applies to all security inks which are transparent before activation. When we place a print at a right place, only someone who knows its placement and ways to detect the special ink effect can identify a given product as original or counterfeited.

Piezochromic inks

Another way to secure the product against counterfeit, copying and forgery can be the use of piezochromic ink. Printing and detection of this security may cause certain issues, however, this solution may aspire to be considered a high-class security. Piezochromic inks react to physical pressure or load or increased ambient pressure. Under pressure, the printed piezochromic ink, initially transparent or colourful, gets coloured or changes colour. Detection of such a security can be done by using e.g. a finger or under the pressure of any object.u.

Its effect could as well be checked in special pressure chambers. To my knowledge, piezochromic inks have not been used as a security before; however, they can become an interesting solution to protect products against forgery.

Hydrochromic and chemochromic inks

Hydrochromic inks change colours or become transparent as the result of contact with water. They come in two variants: reversible and irreversible. In the first case, the ink discolours or changes colour when exposed to water, returning to its initial state after the printout dries out.

In the case of irreversible hydrochromic ink, the effect of water action cannot be turned back. There is no need to use any specialised equipment since we can use a commonly accessible substance in order to check such a printout. Currently, irreversible hydrochromic inks are used in securing cheques and vouchers. An openwork guilloche is printed with the irreversible hydrochromic ink in the area of the cheque or voucher where the owner’s signature is supposed to be placed. When a thief tries to remove a signature with water or other mixture containing water, a guilloche becomes coloured, leaving a stain where the criminal intervened.

Chemochromic inks act quite similarly to hydrochromic inks, except that the factor causing the effect is not water but other chemical substance known to the producer of the ink, which changes, for example, under the influence of ammonia, hydrogen peroxide, or sodium hypochlorite (the active ingredient of clothes’ bleach).

Chemochromic inks come only in irreversible versions. After treating the printout with a developer, they react with colour change or irreversible colouration. A criminal who is trying to revome information or a symbol by using chemical substances (e.g. clothes’ bleach) leaves an irreversible trace of their activity on a label or packaging.

Inks containing substances which react to ammonia are used for detection of this substance in an immediate proximity of a printout. Both hydrochronic and chemochromic inks may be used by a label or packaging producer for securing the product against copying, forgery, or counterfeit in various ways.

The most obvious ones are a small print at a place known only to a producer, which can be checked by using water or other chemical substance (in the case of chemochromic inks, it should be kept in mind that the effect is irreversible). Another way may be to print in the area where a piece of information a criminal is highly likely to attempt to remove will be placed. In such case, a stain will remain visible at a place of attempt to remove a part of a print, exposing an interference.

IR inks

An IR ink is an ink which found wide use in security printing, especially in bank notes, cheques and other valuable documents. A completely transparent printout becomes coloured when treated with a special infrared light emitter. It happens because a special pigment contained in the ink converts infrared into energy visible to the human eye. The effect disappears when the exciting factor – IR light here – goes off. IR inks come in three colours (of course after conversion): yellow, red, and green.

This ink is printed on a unobvious place of a label or packaging, known only to insiders. Detection is made by using IR emitter.

There are special devices, most often in a form of a special „pen” which emits infrared light. After directing it to a place where IR ink had been printed on, a laser dot in yellow, red, or green becomes visible. Directing the laser to a print done with a regular paint or elsewhere will not give an effect of a coloured dot.

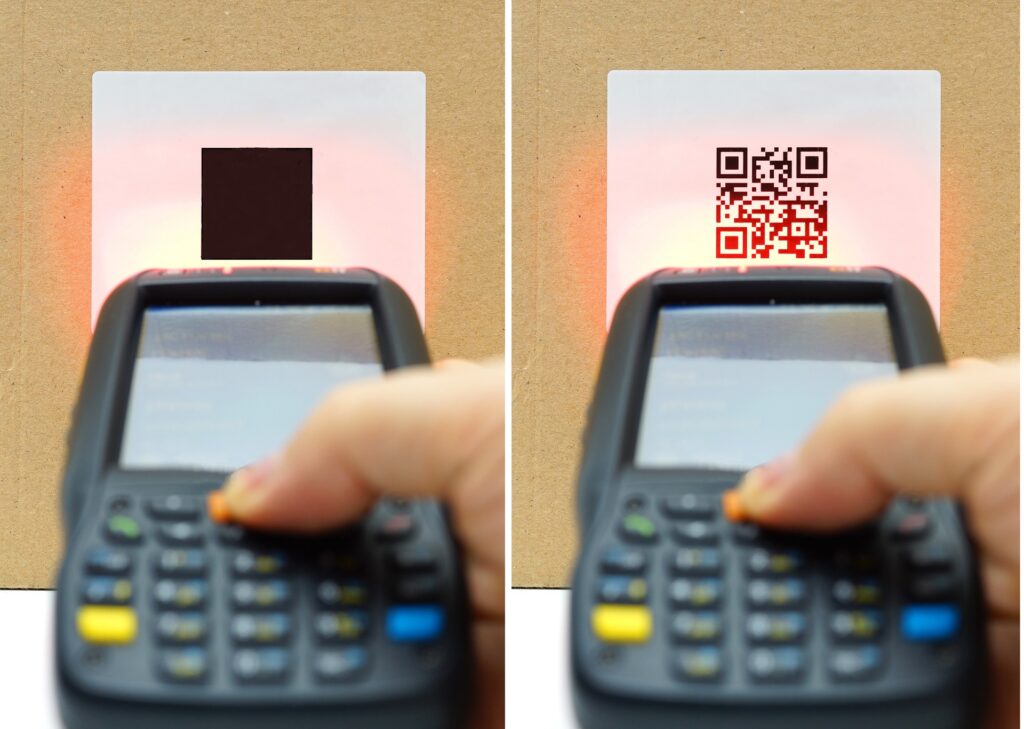

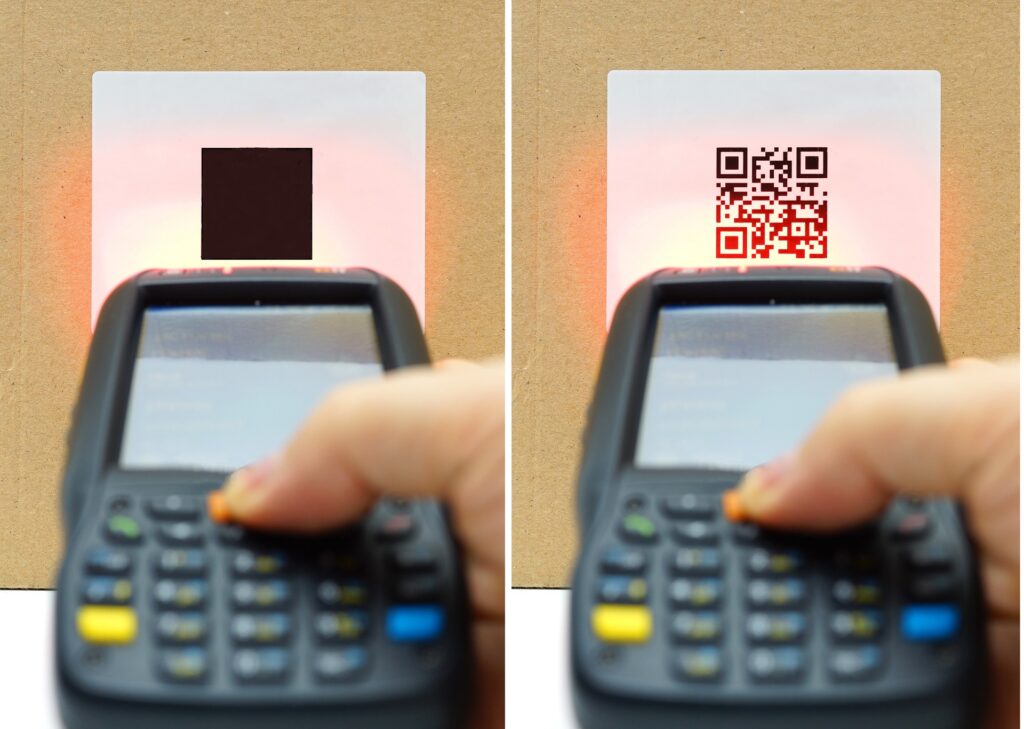

Variations of IR inks are IR-Transparent and IR-non-transparent inks. They form a set of inks in black, where one is „visible” for IR scanners while the other one is not. The IR-non-transparent ink is used for printing barcode or QR code which can be scanned with barcode scanner or IR reader, reading the information they contain. IR-Transparent ink, on the other hand, is used for covering the barcode.

This way, we obtain a black shape, e.g. a rectangle, and the barcode is completely hidden for an end user. IR-Transparent ink does not interfere with the operation of IR scanner since the ink is invisible to it. This hidden barcode or QR code can still be scanned so that one can read coded information..

Phosphorescent inks

Phosphorescent inks, also called „glow-in-the-dark” (often mistakenly named luminescent or photoluminescent inks) are the last type of inks I would like to cover in this part of my study. These inks somewhat „charge” with the energy of UV light (contained in the daylight, parcially in an artificial light, and also in „blacklight” lamp).

This way, the printout, almost completely transparent in light, becomes visible when the surroundings are dark. Detection of authenticity of a label or packaging can be made in a dark room or just by covering them in a way that blocks the access to light; after all, these inks glow in the dark.

Other types of special inks and varnishes for printing protection of labels and packaging against forgery, copying and counterfeit, can be found in the upcoming parts of series about protection of printing.

The original article can be found in periodical Świat DRUKU, issue 9/2022