The use of conductive inks and coatings in printing labels in RFID (Radio-Frequency Identification) system

Energy-conductive inks are not only durable, flexible, and compatible, but also have the ability to transmit and receive selected radio frequencies. Thanks to it, they work well in printing labels in remote radio indentification system (RFID). This technology is present in many devices, passports, credit cards, transportation systems, etc. RFID system is gaining popularity among those customers who need to have constant control over a warehouse or production line and want to significantly facilitate work. How do conductive inks work? How, with their use, are RFID tags printed?

Conductive inks – technology of electricity transport

Conductive coatings have the ability to conduct electricity. It means that a surface coated with special ink gains conductive properties and can transport electricity. The ink consists of a base and particles of highly conductive substance. The most often used are pigments made of graphite or graphene as well as those based on or doped with silver.

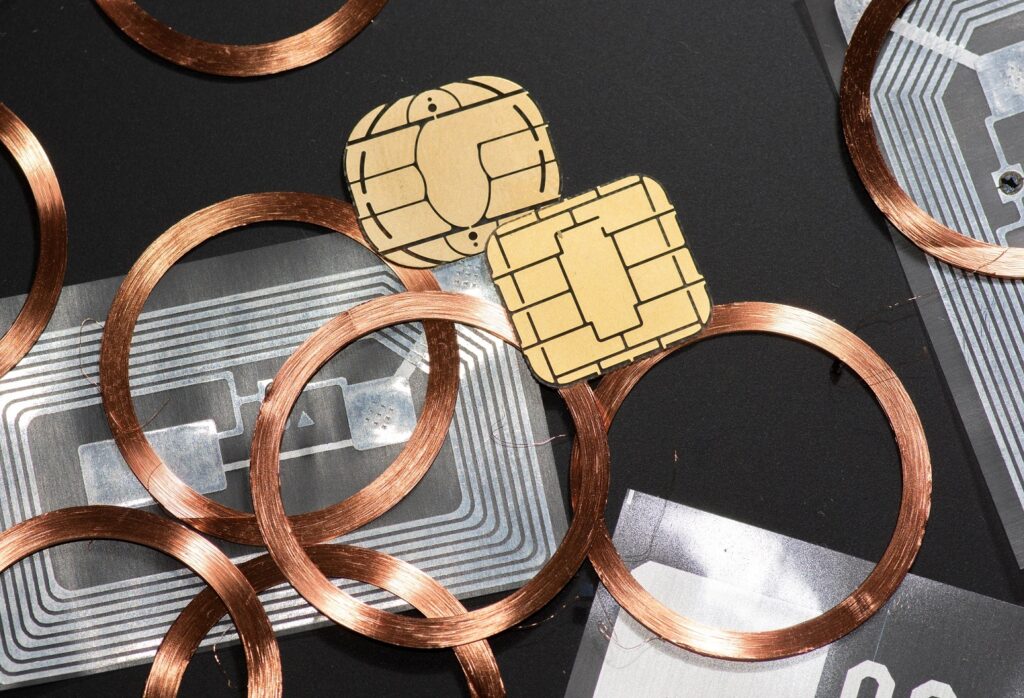

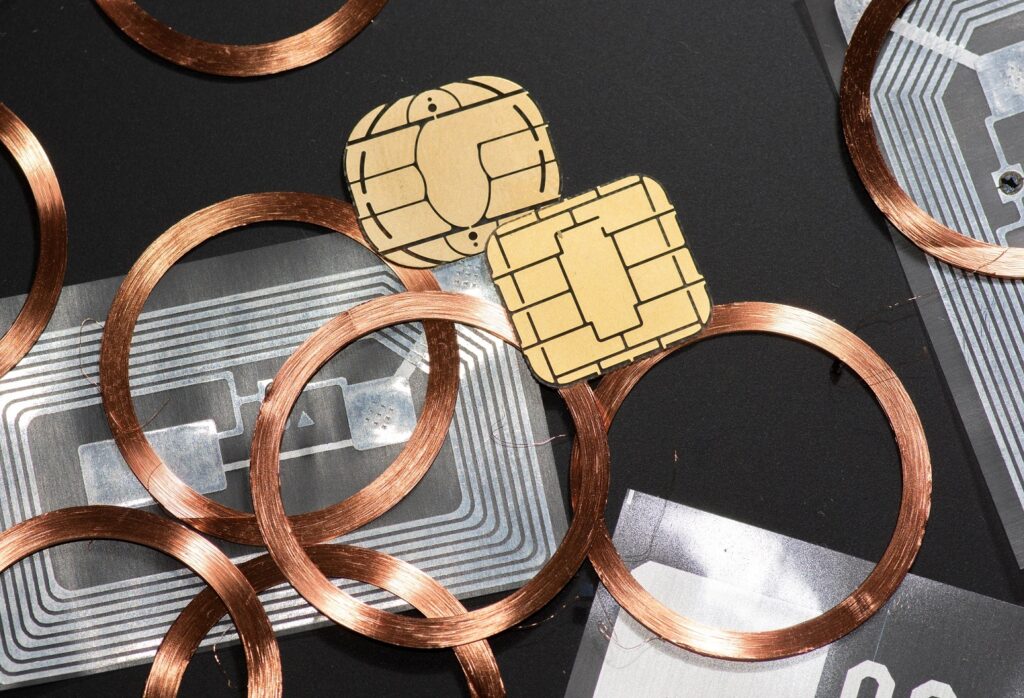

Conductive coatings in printing RFID tags

Remote RFID (Radio-Frequency Identification) system is an alternative to popular barcodes. It allows a wireless identification of selected items using radio frequency. The system consists of a device reading radio signals and the tags that transmit it.

RFID tags do not need batteries which is possible with the use of conductive inks. The tags receive energy via radio waves transmitted from a tag reader. When they hit the surface of an inner aerial, coated with special ink, the energy flows to the integrated circuit. This enables the activation of a chip which converts the energy into a specific piece of information and transmits it back to the reader. Thanks to it, a user receives desired data regarding an item marked with RFID tag.

The advantages of remote RFID radio identification and special inks

The use of energy-conducting inks in RFID system brings numerous benefits. First of all, it is possible to read data from multiple tags at once. This is why this technology is used most often by those people who want to significantly facilitate and speed up work.

RFID system facilitates the supervision of a warehouse or production line. Moreover, a tag does not need to be placed visibly (at it is in the case of classic barcodes, where manual scanning is necessary); it is enough for it to be placed within the reader’s reach.

RFID tags stand out with their high resistance to external factors. Due to the use of special conductive inks, the codes can be placed inside an item. Thanks to it, they will not get damaged due to contamination, extreme temperatures, mechanical damage, or solar radiation.

RFID markers can also serve as a security of a product against counterfeit or theft. The RFID code placed in the packaging or in an item itself (e.g. a book), after crossing special gates, can emit a sound which signals to the salesperson that the product is outside of the store.

They can be used in sales and trade, management of warehouse or transport logistics, in running a returnable packaging management system, in the production and industry, during inventory or control works, identification of people and objects, access control to predefined areas by people or e.g. farm animals and many, many more.

We help you choose a product!

We are here to help you choose a special ink/paint or varnish for your specific project!

Tailor-made products are our specialty.