Wykorzystanie farb przewodzących prąd w przemyśle elektronicznym i elektrotechnicznym

Special paints and inks are present everyday. They are mainly used due to their unique properties which are useful and definitely make every area of life easier. Special varnishes have also found their place in the electronic and electrotechnical industries. A keyword here is mainly conductive paints and inks. Their special ability to conduct energy is used on various ways and often replaces other, classic solutions. How exactly does an electrically conductive paint or ink work? What are the most important qualities of such varnishes? What should one know about using them in the electronic and electrotechnical industries?

How do conductive paints work?

Electrically conductive paints and inks are special coatings which are most often based on epoxy, polyurethane, water-based, or acrylic paints. Their secret which gives them special properties are particles of highly conductive substance. A conductive silver paint is considered one of the most common, but particles of copper, nickel, graphene, graphite, or activated carbon can also be used as conductors.

The most popular are paints and inks based on conductive carbon black mainly due to economical parameters (these conductive paints are relatively inexpensive) but the products with the best of conductors – silver – have the best conductive properties. Since paints and inks based on pure silver are too expensive, producers use tricks to avoid excessive costs, creating pigments where the carrier of silver is glass, copper, or aluminum.

A few words on how to use conductive paints

Before application, surface care should be taken. It should be thoroughly cleaned and dry. Then, you just need to apply the varnish, by using a brush or directly from the packaging, given that it has been equipped with a special applicator (for example, a conductive spray paint). The paint usually dries very fast, even in 10-15 minutes. Since the coating is relatively easy to wash off, a protective varnish which will not affect the conductive properties can be used on top. In the case of painting electronic parts, it is recommended to make sure that they have been coated properly so that the whole system works as expected.

In the case of printing applications, the coating technologies are more complicated. To get the necessary information regarding the application of such inks, one should contact the producer of these inks.

The most important advantages of conductive paints and inks – why are they chosen so often?

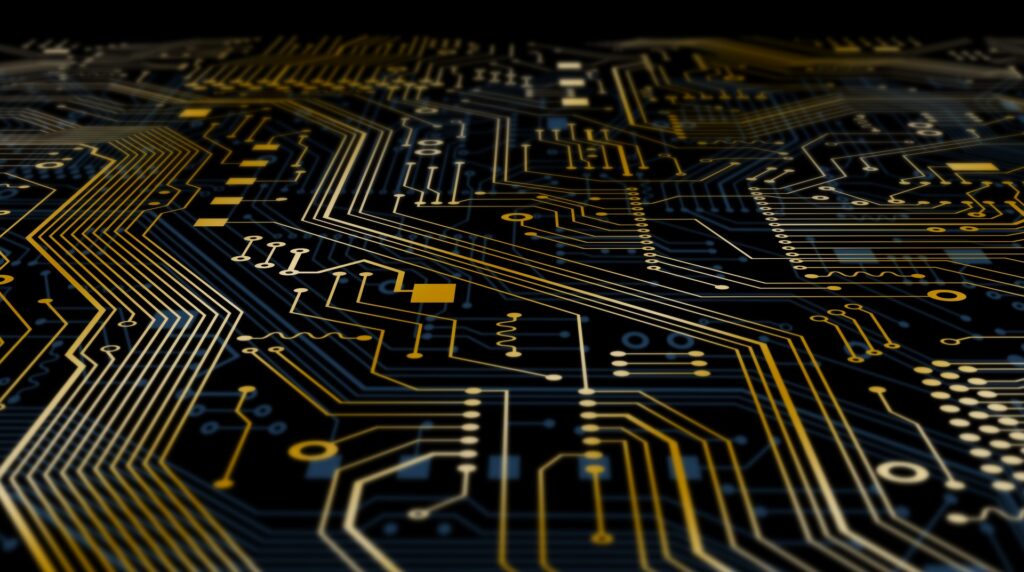

The biggest advantage of electrically conductive paints and inks is the possibility to create modern circuits and plates which enable the transport of the electrical energy. This solution is better than traditional methods in many respects. Compared to the classic industrial standards, it does not require big resources or commitment because printing is relatively simple and inexpensive. Apart from that, inks are unusually lasting. In the case of a high quality ink, the operation time is even several years long. Moreover, conductive paints and inks are versatile and can be used on various materials such as, for example, wood, plastic, paper, glass, and even textiles which makes the possible applications significantly broader.

Conductive paints and inks – the use in the electronic and electrotechnical industries

Usually, electrically conductive paints and inks are used wherever high flexibility and relatively low price of a conductive material are required. They are used, among others, for repairing screens and conductive paths on printed plates. With the help of conductive paints and inks, connecting paths, printed circuits, and contacts’ connections in electronics can be reconstructed. Conductive paints and inks work well wherever selected electronic or electrotechnical elements have to be connected. They can also be used in creating conductive substrates for galvanic processes. The paint or ink also works for temporary repairs and cold soldering where the time and quick reconstruction of e.g. wires are necessary.

The use of conductive paints and inks is very versatile. These inks are used in many industries, beginning from at-home use to medical or defence industries. Conductive paints and inks are used in construction of controllers, sensors, or receivers. They also work as an element of control-and-measuring apparatus. They are used in production of medical and research equipment. They can be seen in all kinds of aerials – for examples, satellites – and in telecommunication devices – for example, radar systems.

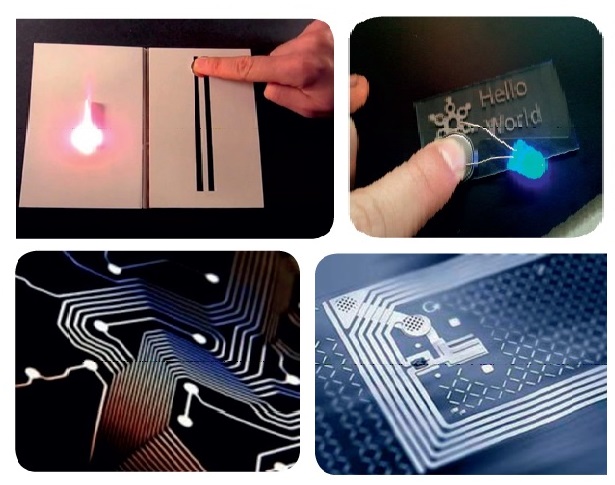

On a daily basis, conductive paints and inks can be seen, for example, in cable television, as well as in creating complex electrical circuits in mobile phones, laptops, and navigation systems. They are also used in consumer electronics, for example, in all kinds of monitors and screens, even in TV sets. On the other hand, a copper-based conductive ink is used in production of audio equipment such as amplification devices and electric guitars. Currently, the use of electrically conductive paints and inks becomes increasingly popular and more often used in creative projects, for example in marketing, especially in all kinds of advertisements – low-voltage conductivity, which is obtained after closing the circuit on a printout with a finger, is the most commonly used.

In defence industry, electrically conductive paints and inks are used in production of GPS receivers as well as electrical equipment and vehicles, for example, drones and other remotely-controlled devices. They are often used in the construction of advanced aerospace applications. These paints and inks are also often used in automotive industry, an example can be the heating of the front and rear windows in order to defrost them.

We help you choose a product!

We are here to help you choose a special ink/paint or varnish for your specific project!

Tailor-made products are our specialty.