Use of Thermochromic Paints for Indicating Desired Temperature on Beverage and Food Labels

Thermochromic paints, known for their sensitivity to temperature changes, play a vital role in modern quality assurance methods. These paints have several advantages, including being cost-effective and efficient, making them a popular choice. How are these thermochromic paints applied to food labeling?

Exploring Different Types of Thermochromic Paints

Among all special paints, thermochromic paints are highly sensitive to all kinds of temperature changes and fluctuations. The color can fade in various ways depending on the type of paint. It can completely lose its color, slightly change its intensity, or transform entirely under the influence of a specific temperature threshold. The most popular pigments fade as the temperature increases, becoming more intense as it decreases.

There are many different types of thermochromic paints. The basic division includes reversible and irreversible ones. The former can disappear under the influence of temperature and reappear when it changes. This process can be repeated multiple times. In the case of irreversible products, the color fades only once and does not return to its previous state. Such changes can be the result of different temperatures specified by the manufacturer.

Dual-range thermochromic paints are also an interesting solution. They lose their color at one temperature and regain it at another. One can also refer to the so-called interval paints, which maintain their color only within a specific temperature range. Another type is liquid crystal thermochromic paints. Due to rising temperatures, they change color in rainbow hues. Currently, many types of thermochromic paints are used for food marking, each serving different purposes.

Labeling Pasteurized Food with Irreversible Thermochromic Inks

National legislations regarding food labeling and proper coding are continuously evolving. Manufacturers of pasteurized food are thus seeking solutions that can help improve product safety and ensure the correct execution of the preservation process. Irreversible thermochromic inks have proven to be one such solution. A significant advantage is their adaptability to various types of packaging, including aluminum cans and food-grade foil. These specialized inks are durable, resistant to smudging, and remain legible.

Thermochromic inks are applied to packaging to ensure that the food has undergone the pasteurization process. They change color within the temperature range of 70 to 115°C (158 to 239°F), providing assurance that the product has been subjected to heat treatment. This is not only a signal to the manufacturer that the batch meets requirements and can be approved for sale, but also to the consumer, who gains awareness of the quality and freshness of the purchased item. In this case, irreversible thermochromic inks are most commonly used, as they suffice to indicate that the process has occurred.

Dual-Range Special Inks and Deep Freezing of Food

An alternative to irreversible thermochromic inks is the dual-range solution. In contrast to the former, dual-range inks can also be used to label extremely low temperatures. The color change occurs only upon reaching the critical temperature. It returns to its original state when the food reaches a significantly lower (usually negative) temperature.

Dual-range thermochromic inks are applied for labeling frozen food. When the food is subjected to unfavorable conditions and higher temperatures, it changes its color. The process can only be reversed by reaching the erasing temperature, which is known only to the manufacturer.

Reversible and Interval Thermochromic Inks for Temperature Monitoring

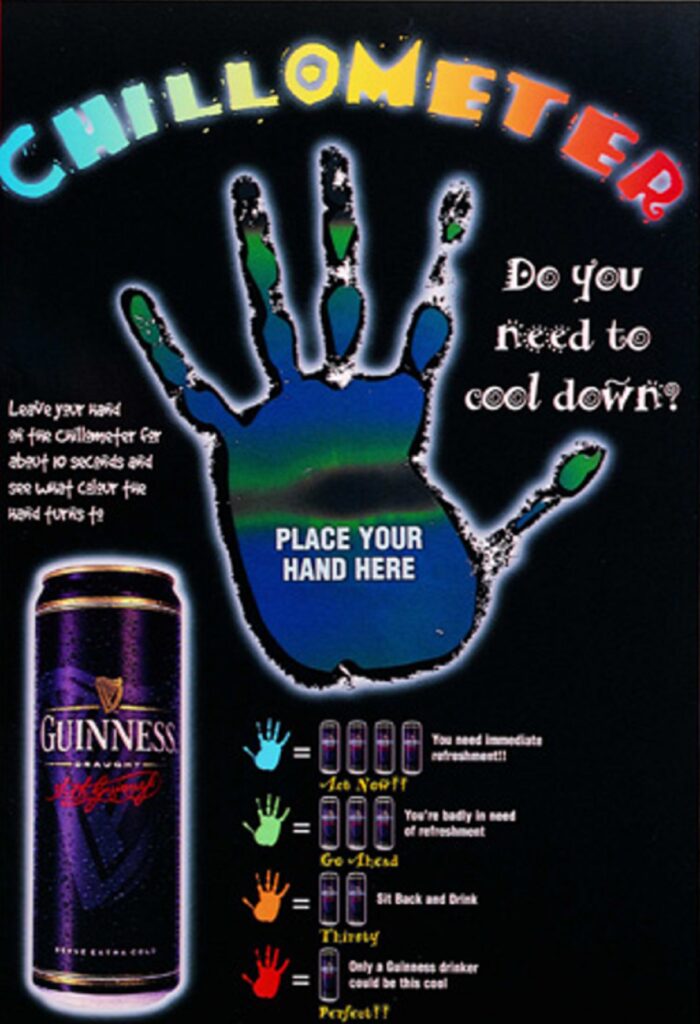

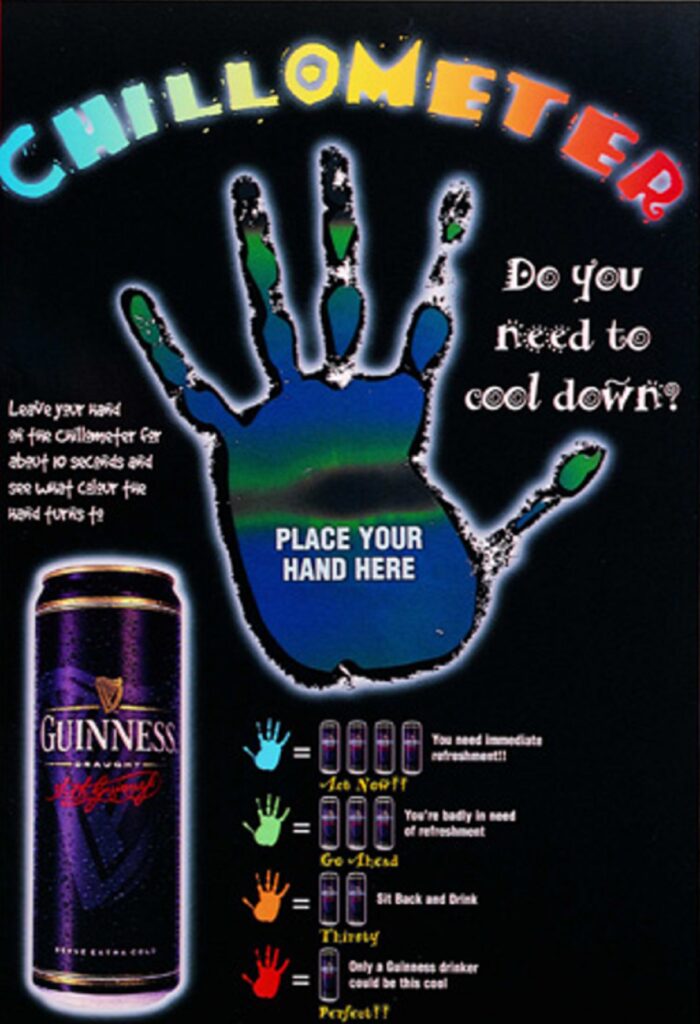

Reversible thermochromic inks find applications in food labeling as well. These inks fade when a precise temperature threshold is reached. Upon subsequent temperature changes, the ink reverts to its original color, making it ideal for labeling beverages. Thermochromic inks serve as indicators of proper product cooling, ensuring optimal consumption conditions. This labeling approach is also useful for ready-to-eat meals. In some cases, manufacturers choose to incorporate printed markers that guide consumers on when the food will be heated to perfection.

Interval thermochromic inks are particularly effective for foods requiring specific temperature ranges. They fade in response to temperatures falling within tightly defined intervals, facilitating control over food storage conditions.

We help you choose a product!

We are here to help you choose a special ink/paint or varnish for your specific project!

Tailor-made products are our specialty.