Security of packaging of tobacco products by well-known brands against counterfeit, copying and forgery

Tobacco products have been very desirable on the market for a long time. Many companies from this industry specialise in production and distribution of these products, and the concept, ideas,and a product itself aer their valuable assets. Unfortunately, there is no shortage of counterfeiters on the matket, who specialise in counterfeiting products. This illegal practice brings massive losses. The frauds usually choose poorly protected products, which are relatively easy to copy. Fortunately, one can protect themself against it. Special inks and varnishes work perfectly for this purpose. There are many possibilities of label security and they are definitely worth using. What is worth knowing about securing tobacco products? Which inks and varnishes work best here?

A short introduction – why are tobacco products being counterfeited?

Along with the development of international trade, there has been an increase in all forms of criminal activities. Smuggling, counterfeit, forgery, copying and other forms of intellectual property infringement are a real nightmare of many industries, including tobacco. Finished products often get appriopriated which results in massive losses. Counterfeiters and thieves save on development costs as well as product certification, taking a finished product, a concept, or an idea away from the companies which have worked hard on achieving their success. This is why, along with the development of crime, there are more ways to prevent it. This is where primarily special inks and varnishes come into play.

Special inks and varnishes in the fight against crime

Among inks, there are currently many products which are perfect for the fight against counterfeit, forgery, or copying. Very often are these products very rarely or almost never used, however they possess enormous potential of product protection.

One of the biggest advantages of this situation is the fact that they are unknown to forgers, therefore tobacco industry can effectively defend itself against these attacks. Only few specialists, who deal with production or protection of products, have knowledge about special inks and varnishes. The inks use physicochemical phenomena, thanks to which are able to not only properly secure packaging, but also to give it an unusual, unique appearance.

Inks for tobacco products – certification

A huge advantage of special inks and varnishes is their adaptability. Certification is necessary in case of tobacco industry. The cigarette boxes are regarded as food packaging, and in this case, the requirement to the use of any inks and varnishes is their adaptation in terms of low migration.

Special inks and varnishes for security – basic types

There are many different types of inks and varnishes for security on the market. Many of them are currently in use in tobacco industry, and some of them still remain an idea worth of developing.

- Invisible colourful fluorescent inks: fluorescent inks visible in UV light in many colours, which enable marking products invisible to the end customer. Invisible white fluorescent inks, on the other hand, are fluorescent inks visible in UV light, emitting super bright, white glow;

- Fluorescent inks visible in daylight: inks with exceptional colour purity, characterised by a bright, neon, intensive glow, which is impossible to be copied. They can be put on the packaging of a tobacco product in the form of signs, guilloches, or inscriptions, effectively protecting the product against counterfeit;

- Phosphorescent inks: phosphorescent inks absorb UV-A radiation and then release it at night. Thanks to this, the authenticity check of a packaging becomes very simple, all it takes is to block the access to light. Usually, the ink remains almost completely transparent, and starts to glow at a dark place. These inks can be divided into a few types, including invisible colourful or white. There are also visible fluorescent inks, because even if they are visible during the day, their appearance and neon glow is impossible to be forged even by using a printer, copying machine, or even a camera;

- Metallic inks: one can also come across metallic silver or gold inks in security. With their exceptional shine, these pigments are very difficult to copy. Firstly, their availability is quite limited, and secondly, the copy does not reflect shiny, shimmering surface of the ink. Apart form being an effective protection, the ink also looks spectacular on the label, in terms of marketing;

- Photochromic inks: a special trait of photochromic inks is that they get coloured just after the contact with UV radiation, which can be sourced from either a special emitter or a sunlight. Such print is completely transparent, and this is why it can be put on any area of the packaging. This way, only someone who knows the area of print and exposes it to the radiation, can confirm the authenticity of the product;

- Thermochromic inks: just as their name suggests, thermochromic inks change colour only when the temperature changes. There are various types of inks which respond to temperature differently. The change can be reversible or not, or can occur in a specific temperature interval. The authenticity check can be carried out in many ways, e.g. by warming up or cooling down the label;

- Piezochromic inks: piezochromic inks can be little bit more complicated, but not any less effective than other types of inks. They react primarily to the load, both as such and as an increased pressure. This is when they change colour most often. The authenticity of the label can be confirmed e.g. by using a finger;

- Hydrochromic and chemochromic inks: the change of colour in hydrochromic inks occurs after contact with water. They come in two types: the colour change is reversible or irreversible. This solution is convenient because water is a universal, easily accessible material, therefore there is no need of a specialised technology to confirm the authenticity if the packaging. In turn, chemochromic inks work almost the same way, except the substance which triggers the colour change is not water but the other substance known to a producer. It is worth noting that the effect of chemochromic ink is irreversible.

Special inks and varnishes for security – other types

- IR inks: inks reacting to the influence of IR with colour appearance;

- IR-Transparent and IR-Non Transparent inks: a set of black inks, one of which is detectible to scanners while the other one is not;

- Electroluminescent inks: inks glowing in various colours after plugging them into the electricity;

- Scented varnishes: varnishes scented with a unique fragrance composition e.g. characteristic only to a given brand;

- Magnetic inks: inks containing ferromagnets, which can be carriers of small amount of information magnetically saved on them (e.g. cards with magnetic stripe)

- Conductive inks: inks having the ability to conduct electricity, the authenticity check of a given product can take place after plugging the printed product into the source of power;

- Scratch-off and erasable inks: inks which can be erased or revealed after rubbing them with various types of tools;

- Copying varnishes: varnishes able to transfer the inscriptions under pen pressure or the influence of temperature

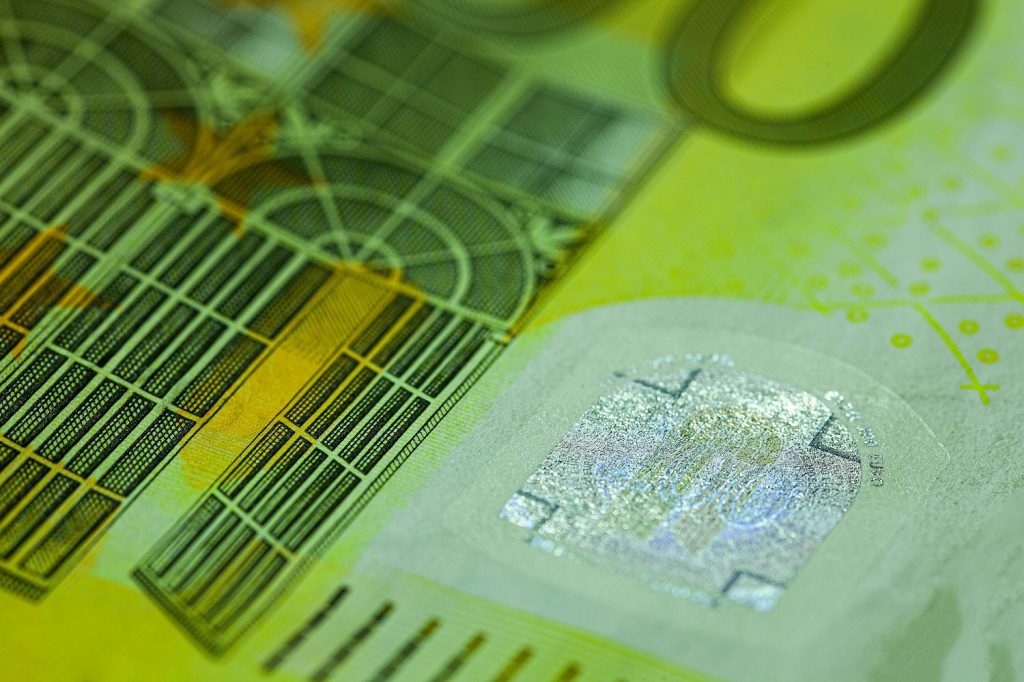

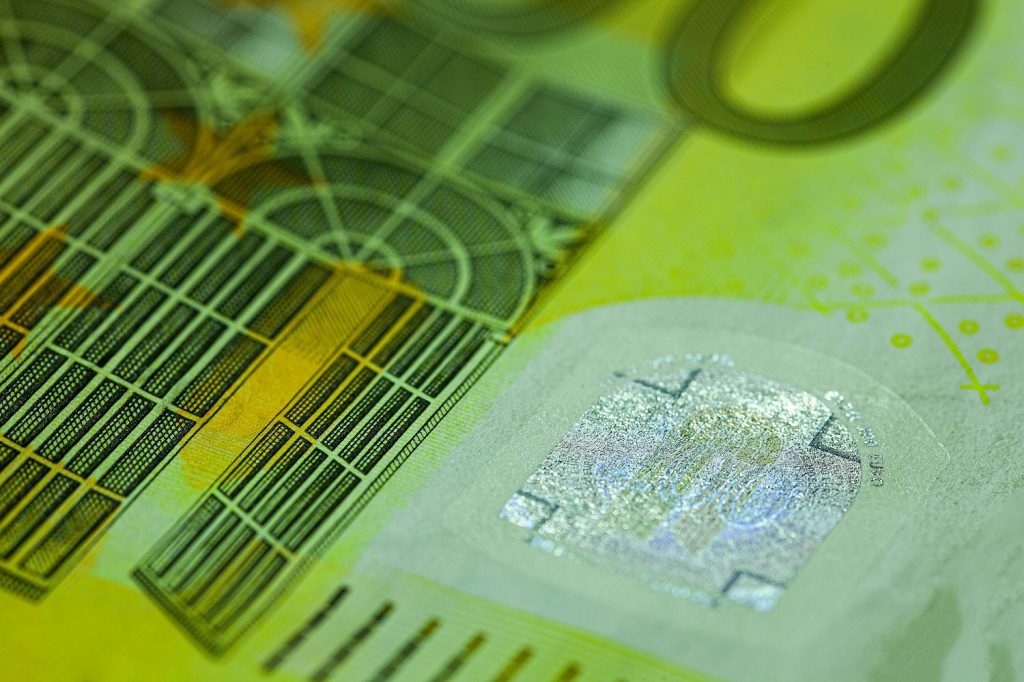

- Optically variable, pearlescent, glitter and interferential varnishes: varnishes wich shimmer in multiple colours, like a rainbow, like pearls, changing colour depending on a viewing angle, perfect for protection of both documents and labels against counterfeit;

- Perceptible varnishes: varnishes which have a texture, thickness or structure which can be felt by hand; by combining various structures and pigments, it is possible to obtain a unique, unusual texture of a label or packaging, specific only to a given brand;

- Watermark varnishes: possible to be printed on regular printing machines, giving off the impression of a watermark, used e.g. in the production of bank notes;

- Penetrating inks: able to absorb into the structure of a substrate, black on the front side and red on the back side.

We help you choose a product!

We are here to help you choose a special ink/paint or varnish for your specific project!

Tailor-made products are our specialty.