UV paints and varnishes for wood, furniture and furniture edges

Fields of construction elements and furniture elements made of wood belong to the fastest-growing branches of industry in Poland. Same goes for PVC panels. The fields of wood, furniture and PVC panels’ coatings by using paints and varnishes cured by UV or LED are dynamically growing areas of coating industry within the aforementioned two sectors.

Used by producers of furniture, kitchen furniture sets, exterior and interior doors, furniture panels, floor and wall panels, floors, PVC panels for both indoor and outdoor use and furniture edges.

UV/LED curing allows production facilities to save money and space. Products coated with UV/LED varnishes or paints can be further processed immediately after application. They also do not need production spaces needed for drying required in other coating technologies (such as e.g. water-based applications), because varnished surfaces are cured immediately after exiting the machine.

UV/LED coatings are incredibly durable, hard and resistant to weather and environmental conditions and are VOC-free, so they do not emit harmful vapours. Their additional advantages are parameters such as: relatively low tendency to yellowing, very high elasticity, low own odour, very good adhesion to substrates, also synthetic ones such as e.g. PVC, ABS, PC or PS, high resistance to migration of plasticisers in a substrate, excellent print quality, exceptional gloss and noble finish.

UV/LED PAINTS AND VARNISHES FOR PVC COATINGS

Rotogravure printing, roller application and curtain application by using UV / LED paints and varnishes are ones of the most important and fastest-growing methods of printing and coating of PVC panels.

Developed especially for printing on PVC panels, they have good adhesion to paper, cardboars and OPP laminating foil.

They show good elasticity to the substrate, are susceptible to folding and bending, and also have low own odor.

Selected series of paints and varnishes are used for outdoor applications, on PVC wall panels. These are characterized by a very high lightfastness, resistance to weather and environmental conditions as well as durability over time.

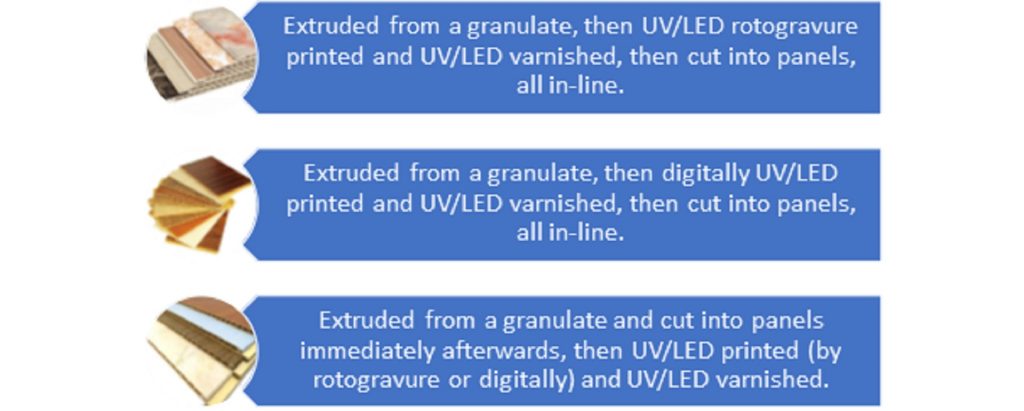

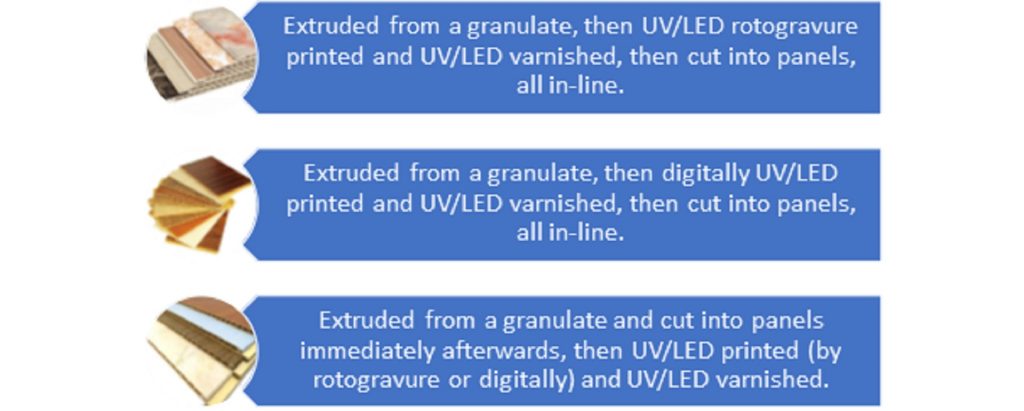

THERE ARE THREE TYPES OF WALL PANELS MADE OF PVC

THE DRAWING IS BEING PRINTED BY UV/LED ROTOGRAVURE, THEN UV/LED VARNISHED

EACH PRODUCTION REQUIRES QUALITY CONTROL OF PRODUCED PVC PANELS. ADHESION, COLOUR, LIGHT FASTNESS AS WELL AS RESISTANCES TO SCRATCHES, TEMPERATURE AND WATER ARE TESTED

PAINTS AND VARNISHES FOR EDGE BANDS (FURNITURE VENEERS)

Printing and coating of furniture edges and veneers with UV/LED paints and varnishes are ones of the most efficient and effective methods of coating them with a pattern or a drawing imitating wood, stone or other decorations.

LUV/LED varnishes, ont he other hand, are used for effective and durable protection against scratching, abrasion and further processing, as well as for giving them excellent gloss and decorative effect.

Series of UV/LED cured paints and varnishes, designed for refinement of furniture edges, profiles and extruded panels, allow to obtain an effect of imitation of wood or marble as well as other multicoloured effects.

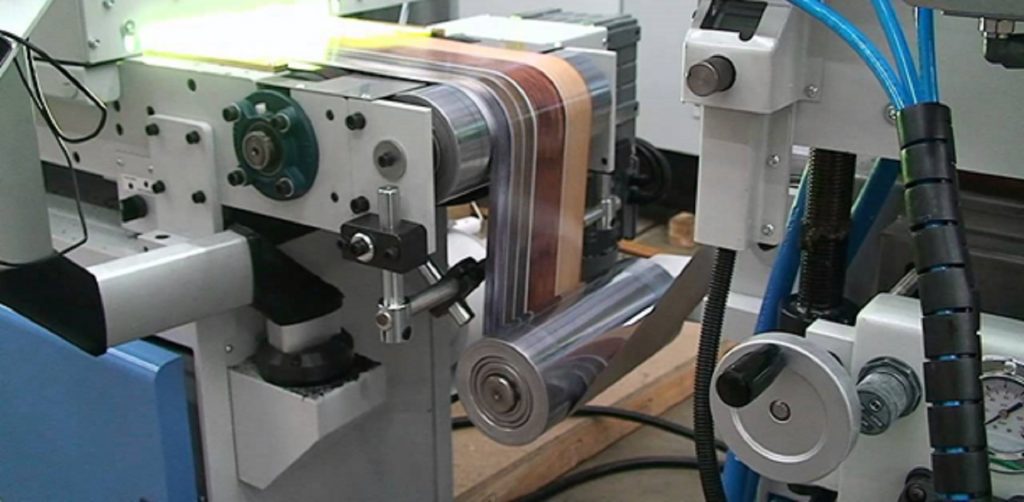

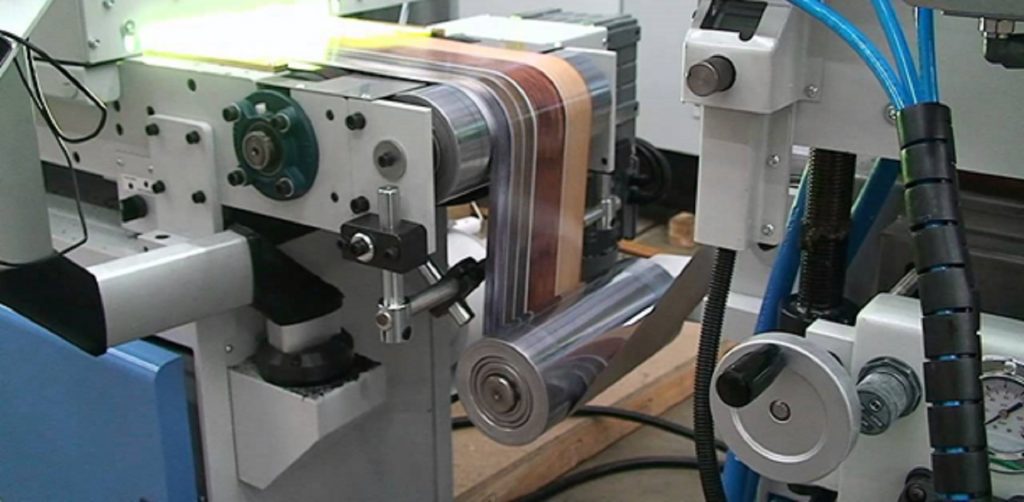

They are printed in UV/LED indirect rotogravure and UV/LED flexo technologies. They are characterised by good adhesion to PVC, ABS, PC and PS, high resistance to migration of plasticisers in a substrate, excellent print fidelity, the possibility of very fast refining and finishing processing after printing and excellent shine.

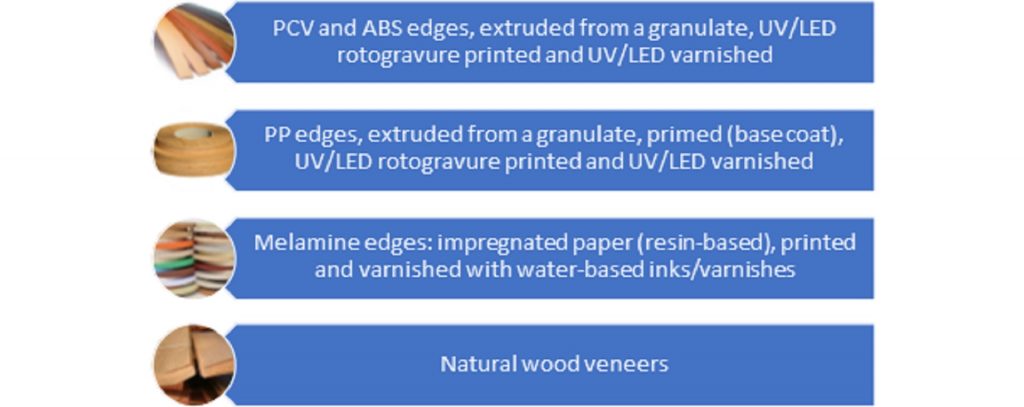

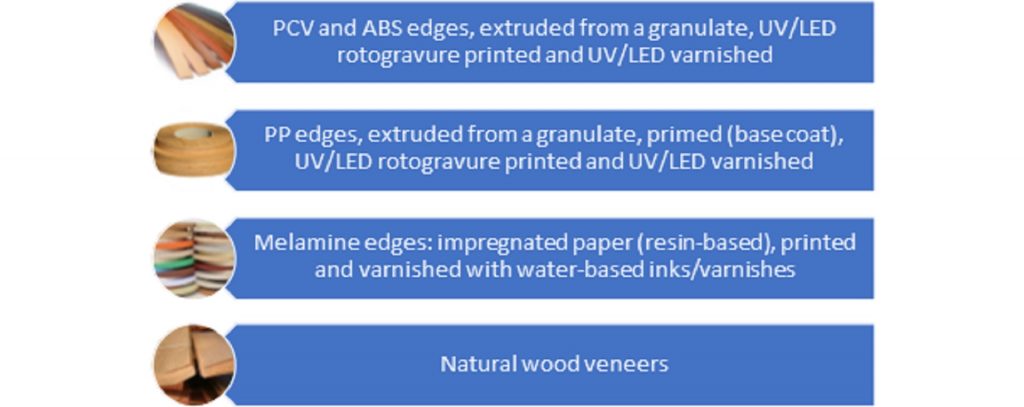

FOUR TYPES OF FURNITURE VENEERS

UV/LED INDIRECT ROTOGRAVURE PRINTING PLUS VARNISHING

QUALITY CONTROL REQUIREMENTS

SPRAYABLE VARNISHES FOR WOOD AND FURNITURE

Spraying UV/LED varnishes by using airbrush, spray and high pressure spray is a convenient and effective method od coating wooden boards, countertops and elements of furniture.

These varnishes are characterised by good adhesion to previously treated substrates (adhesion to other substrates should be checked before application), good elasticity enabling easy bending or folding, low own odour, very high solid content and very low VOC content.

They can be dried quickly and safely. They are suitable for application by using conventional spray or high pressure systems.